Operator's manual

Operator's manual. Ventilation system

1. ANNOTATION

This manual contains instructions for the operator to work with the ventilation system, describes its block diagram, the control logic of the controllers and the operator panel, offers a list of actions to find the causes of possible malfunctions and ways to eliminate them.

CONTENT

1. ABSTRACT

2. PURPOSE OF THE PROGRAM

3. PROGRAM PERFORMANCE

3.1 Structural diagram of ventilation system control

3.2 Description of the control cabinet

3.3 Description of operator panel control modes

3.4 Description of video frames

3.4.1. Video frame "Inlet system P14"

3.4.2 Video frame "Exhaust system B14"

3.4.3. Video frame "Recirculation R14"

3.4.4. Video frame "Measurements P14"

3.4.5. Video frame "R14 measurements"

3.4.6. Video frame "Inlet system P17"

3.4.7. Video frame "Exhaust system B29"

3.4.8 Video frame "P17 measurements"

3.4.9 Video frame "Inlet system P18"

3.4.11 Video frame "Exhaust system B30"

3.4.12 Video frame "P18 measurements"

3.4.13 Video frame "P18 measurements"

4. Description of the algorithm

5. Faults

5.1 Faulty frequency drive (FCD)

5.2 Sensor failures

5.3 Personnel actions in case of controller failure

5.4 Decommissioning the control cabinet

5. The procedure for checking the performance of the ventilation system

7. Sheet of accounting for changes

2. PURPOSE OF THE PROGRAM

The ventilation systems are controlled by motors, three-way valves for mixing hot water into the heating circuits and damper actuators to ensure air exchange.

The visualization system provides a display on the video frames of the panel of current information about the state of the unit, operating modes, and also allows you to control ventilation.

3. PROGRAM PERFORMANCE

3.1 Structural diagram of ventilation system control

Structural diagram with IP320

Figure 1. Structural diagram of ventilation system control

This structure implements a hierarchical subordination scheme between nodes and components that make up the ventilation control system. Each of the three controllers provides control of slave equipment, consisting of several frequency drives and several I / O modules. Each controller, in turn, is subordinate to the IP320 panel, which is the master (network component) in this structure.3.2 Description of the control cabinet

Figure 2. Video frame "Appearance of the control cabinet"

The control system has been designed with minimal maintenance in mind. So, for example, when the voltage is restored after a drop in the network, the system is automatically initialized and put into operation - the ventilation turns on and starts to regulate the temperature in the premises. The values set before the voltage drop on the system regulators are set to default values, all systems start to work in automatic mode.

The IP320 operator panel is located in the central part of the cabinet.

Inside the cabinet there are three OWEN PLCs and six I / O modules, frequency drives (FCV) are located in the cabinet of frequency drives (located nearby).

3.3 Description of operator panel control modes

Each of the subsystems is controlled separately in automatic mode.

Automatic mode is a mode that does not require operator intervention. The control loop stabilizes the temperature value TE3 (outlet temperature in the room) at the level set by the operator from the panel. The operator has the ability to enable and disable each of the subsystems, reduce or increase the set temperature.

3.4 Description of video frames

The human-machine interface system consists of twelve video frames, which are designed to monitor the condition and control the ventilation system.

The composition and functionality of video frames is as follows:

1. Control P14;

2. Control B14;

3. R14 control;

4. P14 measurements;

5. R14 measurements;

6. Management P17;

7. Control B29;

8. P17 measurements;

9. Management P18;

10. Control B30;

11. P18 measurements;

12. Change of season.

3.4.1. Video frame "Inlet system P14"Figure 3. Video frame "Inlet system P14"

This video frame is the first to appear on the screen after the system is turned on. It can also be called at any time by pressing ESC, the leftmost button on the panel in the bottom row.

This video frame is designed to turn on and off the supply system P14, change the speed of the asynchronous motor, indicate the state of the supply system, and indicate emergency events.

1. The names of the subsystems are located at the top of the screen.

In the upper right part of the video frame, a “running number” is displayed, showing the operability of digital communication with the controller, and also confirms the operability of the controller. If this value does not change, this may be a symptom of a problem with the controller or communication with it.

2. In the middle of the screen there are hints for the control buttons.

The operation of the system is controlled by pressing the buttons on the panel located on the right.

Attention: the panel does not have a touchscreen function. Use the number buttons to issue commands according to the prompts.

Pressing the button "1" on the panel on the right starts the sequence of switching on the supply system P14.

When button "2" is pressed, the sequence of switching off the supply system P14 is started.

Pressing button "3" confirms the current violation by the operator.

3. Dynamically changing fields are displayed at the bottom of the screen showing system status and violations.

List of possible states:

"Disabled": means the system is not running, the fans are off, the damper is closed, the hot water valve is closed.

"Winter/summer": Appears at startup, means the system is checking if heating is required.

Preheat: Indicates that the system is preheating the radiator.

"Valve 100%": means that the control valve is 100% open.

"Incl. pump": Appears when the hot water pump is confirmed to be on.

"Warming up?": This message occurs when the system evaluates the degree of heating of the radiator at startup.

"Honored. open": means that the gate is opening.

Drives on: means that both fans on the supply and exhaust ducts are turned on.

"Season Selection": This message occurs while the system is evaluating the need to enter temperature control mode.

"All disable": means that the equipment is being turned off.

"T regulation": means that the system is working according to the PID law.

"Unregulated": means that the system supplies air to the room without heating.

"Defrost": means that the algorithm to protect the heatsink from damage is being implemented.

Attention: the transition from one video frame to another is carried out using the buttons and located on the panel in the bottom row.

3.4.2 Video frame "Exhaust system B14"Figure 4. Video frame "Exhaust system B14»

This video frame is designed to enable and disable the B14 exhaust system, change the speed of the asynchronous motor, indicate the state of the exhaust system, and indicate emergency events.

1. The names of the subsystems are located at the top of the screen.

In the upper right part of the video frame, a “running number” is displayed, showing the operability of digital communication with the controller, and also confirms the operability of the controller. If this value does not change, this may be a symptom of a problem with the controller or communication with it.

2. In the middle of the screen there are hints for the control buttons.

The operation of the system is controlled by pressing the buttons on the panel located on the right.

Attention: the panel does not have a touchscreen function. Use the number buttons to issue commands according to the prompts.

By pressing the button "1" on the panel on the right, the activation sequence of the exhaust system B14 starts.

Pressing the button "2" starts the sequence of switching off the exhaust system B14.

Pressing button "3" confirms the current violation by the operator.

3. Dynamically changing fields are displayed at the bottom of the screen showing system status and violations.

List of possible states:

"Enabled": means the system is extracting air from the room.

«Отключена»: означает, что вытяжная система не работает, вентилятор выключен, шибер закрыт.

Fault: Indicates that an engine problem has been diagnosed.

Attention: the transition from one video frame to another is carried out using the buttons and located on the panel in the bottom row.

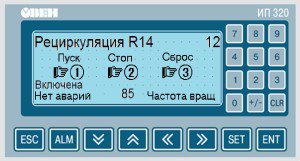

3.4.3. Video frame "Recirculation R14"Figure 5. Video frame "Recirculation R14"

This video frame is designed to enable and disable the R14 recirculation system, change the speed of the asynchronous motor, indicate the status of the R14 recirculation system, and indicate emergency events.

1. The names of the subsystems are located at the top of the screen.

In the upper right part of the video frame, a "running number" is displayed, which shows the operability of digital communication with the controller, and also confirms the operability of the controller. If this value does not change, this may be a symptom of a problem with the controller or communication with it.

2. In the middle of the screen there are hints for the control buttons.

The operation of the system is controlled by pressing the buttons on the panel located on the right.

Attention: the panel does not have a touchscreen function. Use the number buttons to issue commands according to the prompts.

Pressing button "1" on the panel on the right starts the activation sequence of the R14 recirculation system.

Pressing button "2" starts the sequence of the recirculation system R14.

Pressing button "3" confirms the current violation by the operator.

3. Dynamically changing fields are displayed at the bottom of the screen showing system status and violations.

List of possible states:

"Enabled": means the system is extracting air from the room.

"Disabled": means that the recirculation system is not working, the fan is off, the damper is closed.

Fault: Indicates that an engine problem has been diagnosed.

Attention: the transition from one video frame to another is carried out using the buttons and located on the panel in the bottom row.

3.4.4. Video frame "Measurements P14»

Figure 6. Video frame "Measurements P14»

This video frame is designed to measure and control the temperature of the air supplied to the room.

SP_TE1: outdoor air temperature setpoint. Used for seasonal transition winter-summer.

SP_TE2: Return water temperature setpoint. It is used to protect the circuit from freezing during the cold season.

SP_TE3: setpoint for the temperature of the air supplied to the room.

TE1: Actual outdoor temperature.

TE2: Actual return temperature.

TE3: Actual temperature of the air supplied to the room.

3.4.5. Video frame "R14 measurements"

Figure 7. Video frame "Measurements R14»

This video frame is designed to measure the temperature in the air recirculation zone.

SP_TE4: temperature setpoint in the recirculation zone.

TE4: actual temperature value in the recirculation zone.

3.4.6. Video frame "Inlet system P17»

Figure 8. Video frame "Inlet system P17»

This video frame is designed to enable and disable the supply system P17, change the speed of the asynchronous motor, indicate the status of the supply system, and indicate emergency events.

1. The names of the subsystems are located at the top of the screen.

In the upper right part of the video frame, a “running number” is displayed, showing the operability of digital communication with the controller, and also confirms the operability of the controller. If this value does not change, this may be a symptom of a problem with the controller or communication with it.

2. In the middle of the screen there are hints for the control buttons.

The operation of the system is controlled by pressing the buttons on the panel located on the right.

Attention: the panel does not have a touchscreen function. Use the number buttons to issue commands according to the prompts.

When you press the button "1" on the panel on the right, the start of the sequence of switching on the supply system P17 starts.

Pressing the button "2" starts the sequence of switching off the supply system P17.

Pressing button "3" confirms the current violation by the operator.

3. Dynamically changing fields are displayed at the bottom of the screen showing system status and violations.

List of possible states:

"Disabled": means the system is not running, the fans are off, the damper is closed, the hot water valve is closed.

"Winter/summer": Appears at startup, means the system is checking if heating is required.

Preheat: Indicates that the system is preheating the radiator.

"Valve 100%": means that the control valve is 100% open.

"Incl. pump": Appears when the hot water pump is confirmed to be on.

"Warming up?": This message occurs when the system evaluates the degree of heating of the radiator at startup.

"Honored. open": means that the gate is opening.

Drives on: means that both fans on the supply and exhaust ducts are turned on.

"Season Selection": This message occurs while the system is evaluating the need to enter temperature control mode.

"All disable": means that the equipment is being turned off.

"T regulation": means that the system is working according to the PID law.

"Unregulated": means that the system supplies air to the room without heating.

"Defrost": means that the algorithm to protect the heatsink from damage is being implemented.

Attention: the transition from one video frame to another is carried out using the buttons and located on the panel in the bottom row.

3.4.7. Video frame "Exhaust system B29»

Figure 9. Video frame "Exhaust system B29»

This video frame is designed to enable and disable the B29 exhaust system, change the speed of the asynchronous motor, indicate the state of the exhaust system, and indicate emergency events.

1. The names of the subsystems are located at the top of the screen.

In the upper right part of the video frame, a “running number” is displayed, showing the operability of digital communication with the controller, and also confirms the operability of the controller. If this value does not change, this may be a symptom of a problem with the controller or communication with it.

2. In the middle of the screen there are hints for the control buttons.

The operation of the system is controlled by pressing the buttons on the panel located on the right.

Attention: the panel does not have a touchscreen function. Use the number buttons to issue commands according to the prompts.

Pressing the button "1" on the panel on the right starts the activation sequence of the exhaust system B29.

Pressing button "2" starts the exhaust system shutdown sequence B29.

Pressing button "3" confirms the current violation by the operator.

3. Dynamically changing fields are displayed at the bottom of the screen showing system status and violations.

List of possible states:

"Enabled": means the system is extracting air from the room.

"Disabled": means that the exhaust system is not working, the fan is off, the damper is closed.

Fault: Indicates that an engine problem has been diagnosed.

Attention: the transition from one video frame to another is carried out using the buttons and located on the panel in the bottom row.

3.4.8 Video frame "P17 measurements"

Figure 10. Video frame "Measurements P17»

This video frame is designed to measure and control the temperature of the air supplied to the room.

SP_TE1: outdoor air temperature setpoint. Used for seasonal transition winter-summer.

SP_TE2: Return water temperature setpoint. It is used to protect the circuit from freezing during the cold season.

SP_TE3: setpoint for the temperature of the air supplied to the room.

TE1: Actual outdoor temperature.

TE2: Actual return temperature.

TE3: Actual temperature of the air supplied to the room.

3.4.9 Video frame "Inlet system P18"Figure 11. Video frame "Inlet system P18»

This video frame is designed to enable and disable the supply system P18, change the speed of the asynchronous motor, indicate the status of the supply system, and indicate emergency events.

1. The names of the subsystems are located at the top of the screen.

In the upper right part of the video frame, a “running number” is displayed, showing the operability of digital communication with the controller, and also confirms the operability of the controller. If this value does not change, this may be a symptom of a problem with the controller or communication with it.

2. In the middle of the screen there are hints for the control buttons.

The operation of the system is controlled by pressing the buttons on the panel located on the right.

Attention: the panel does not have a touchscreen function. Use the number buttons to issue commands according to the prompts.

Pressing the button "1" on the panel on the right starts the sequence of switching on the supply system P18.

Pressing button "2" starts the sequence of switching off the supply system P18.

Pressing button "3" confirms the current violation by the operator.

3. Dynamically changing fields are displayed at the bottom of the screen showing system status and violations.

List of possible states:

"Disabled": means the system is not running, the fans are off, the damper is closed, the hot water valve is closed.

"Winter/summer": Appears at startup, means the system is checking if heating is required.

Preheat: Indicates that the system is preheating the radiator.

"Valve 100%": means that the control valve is 100% open.

"Incl. pump": Appears when the hot water pump is confirmed to be on.

"Warming up?": This message occurs when the system evaluates the degree of heating of the radiator at startup.

"Honored. open": means that the gate is opening.

Drives on: means that both fans on the supply and exhaust ducts are turned on.

"Season Selection": This message occurs while the system is evaluating the need to enter temperature control mode.

"All disable": means that the equipment is being turned off.

"T regulation": means that the system is working according to the PID law.

"Unregulated": means that the system supplies air to the room without heating.

"Defrost": means that the algorithm to protect the heatsink from damage is being implemented.

Attention: the transition from one video frame to another is carried out using the buttons and located on the panel in the bottom row.

3.4.10 Video frame "Exhaust system B30»Figure 12. Video frame "Exhaust system B30»

This video frame is designed to enable and disable the B30 exhaust system, change the speed of the asynchronous motor, indicate the state of the exhaust system, and indicate emergency events.

1. The names of the subsystems are located at the top of the screen.

In the upper right part of the video frame, a “running number” is displayed, showing the operability of digital communication with the controller, and also confirms the operability of the controller. If this value does not change, this may be a symptom of a problem with the controller or communication with it.

2. In the middle of the screen there are hints for the control buttons.

The operation of the system is controlled by pressing the buttons on the panel located on the right.

Attention: the panel does not have a touchscreen function. Use the number buttons to issue commands according to the prompts.

Pressing button "1" on the panel on the right starts the activation sequence of the exhaust system B30.

Pressing button "2" starts the B30 exhaust system shutdown sequence.

Pressing button "3" confirms the current violation by the operator.

3. Dynamically changing fields are displayed at the bottom of the screen showing system status and violations.

List of possible states:

"Enabled": means the system is extracting air from the room.

"Disabled": means that the exhaust system is not working, the fan is off, the damper is closed.

Fault: Indicates that an engine problem has been diagnosed.

Attention: the transition from one video frame to another is carried out using the buttons and located on the panel in the bottom row.

3.4.11 Video frame "P18 measurements"Figure 13. Video frame "P18 measurements"

This video frame is designed to measure and control the temperature of the air supplied to the room.

SP_TE1: outdoor air temperature setpoint. Used for seasonal transition winter-summer.

SP_TE2: Return water temperature setpoint. It is used to protect the circuit from freezing during the cold season.

SP_TE3: setpoint for the temperature of the air supplied to the room.

TE1: Actual outdoor temperature.

TE2: Actual return temperature.

TE3: Actual temperature of the air supplied to the room.

3.4.12 Video frame “Season measurements”Figure 14. Video frame “Season measurements”

This video frame is designed to adjust the seasonal settings of ventilation units.

On the left, the status is indicated, in which season the ventilation unit is located for supply systems 14, 17 and 18.

On the right are the seasons and the teams to switch them.

In order to change the season for the supply system 14 to summer, press button "1" on the panel on the right, to winter - button "2".

To change the season for the supply system 17 to summer, press button "3" on the panel on the right, to winter - button "4".

To change the season for the supply system 18 to summer, press button "5" on the panel on the right, to winter - button "6".

Attention: the panel does not have a touchscreen function. Use the number buttons to give commands as prompted.

4. Description of the algorithm

Figure 15. Graphical description of the work algorithm

The supply ventilation system is controlled in accordance with the graphic description shown above.

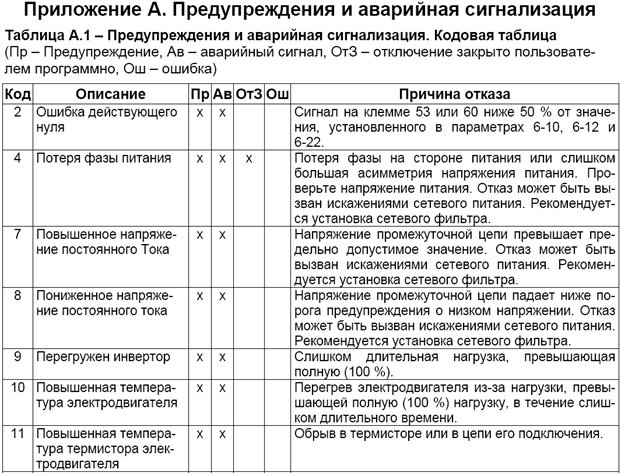

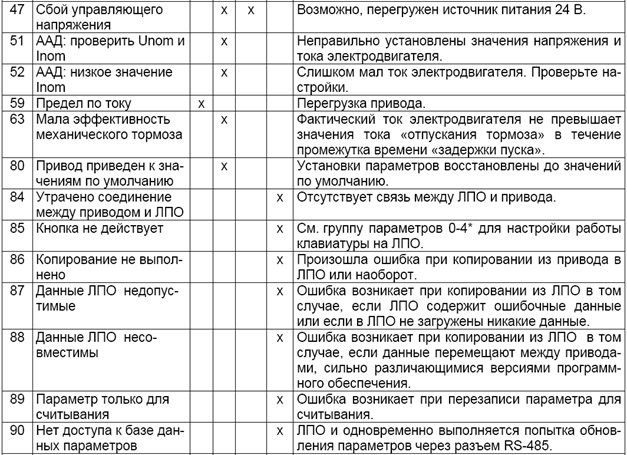

5. Faults

This section describes possible malfunctions of the system or its parts, causes and remedies.

5.1 Faulty frequency drive (FCD)

Malfunctions of frequency drives are associated with a malfunction of the fan drives. The probability of false positives of the frequency converter is unlikely. The indication of these errors is displayed on the front panel of the frequency converter (frequency drives) inside the cabinet of frequency drives.

5.2 Sensor failures

The controller analyzes the quality of data received from temperature sensors and pressure sensors. In the event of a sensor malfunction due to data going beyond the measurement limits (open or short circuit of the sensor, malfunction of the sensor itself), the sensor values on the panel will be brought to the value “1.11”.

5.3 Personnel actions in case of controller failure

1. Unscrew the covers of the regulator drives and remove the first blue wire, having previously insulated it. This will ensure that the power supply to the drive is interrupted. After that, use the drive handle to unscrew it to the desired degree of opening.

2. Open the cabinet with frequency drives, insert the front panel on each frequency drive and put the drives into the "stop" state.

3. Switch on the drives in manual mode.

4. Check the direction of rotation of the drives.

5.4 Decommissioning the control cabinet

If it is necessary to turn off all ventilation subsystems, it is necessary to turn off the automatic power supply of each controller.

5. The procedure for checking the performance of the ventilation system

1. Turn on the ventilation unit and make sure that air comes out of the supply air ducts and is drawn into the exhaust ducts.

2. Check with tactile sensations (by touch) that there is hot water in the pipes that lead to the ventilation unit.

3. Make sure that the system is turned on and working (state "Adjustment T").

4. Set the value of SP_TE3 to the maximum limit of 25 C and wait until TE3 begins to increase to the set value. If this does not happen, then either the regulator is faulty, or there is a problem with the water supply to the coolant supply circuit.

5. With the system running, disconnect the temperature sensor TE2 from the hot water pipe. When cooling down, the sensor should stop the system and put it into defrost mode.

6. Check the functionality of the defrost capillary sensor. To do this, unscrew the temperature adjustment screw to the maximum clockwise. In this case, the sensor should work and start the defrost mode.

In the defrost mode, the supply fan is turned off (the exhaust fan remains in operation), the pump turns on, the valve opens to 100%.

#OWEN, #Operatormanual, #Ventilationsystem, #PLK110, #IP320

Be the first to comment