Terms of Reference for Automation

Development of application software for the controller and operator panel

Technical task

PROJECT NUMBER

2021

ANNOTATION

This document contains the test program and test procedure (PMI) of the applied software (SW) for series B series DC boards manufactured by JSC "Customer" installed at the Power Plant.

The terms of reference define the technical requirements, stages and stages of development, composition operational documentation, as well as the procedure for control and acceptance of PPO for shields DC V.

CONTENT

1. INTRODUCTION

1.1. Development name

1.2. Application area

2. BASIS FOR DEVELOPMENT

2.1. Name of the Contractor's enterprise and its details

2.2. Name of the Customer's enterprise and its details

2.3. The list of documents on the basis of which the PPO is created

3. PURPOSE OF THE DEVELOPMENT

4. REQUIREMENTS FOR THE PROGRAM

4.1. General software requirements

4.1.1. Information Panel Tool Software Requirements

4.1.2. PLC application software requirements

4.1.3. Application software requirements for receiving data via Modbus RTU

4.2. Requirements for the functional characteristics of software

4.2.1. General requirements

4.2.2. Information display and signaling requirements

4.2.3. Information archiving requirements

4.2.4. Speed Requirements

4.2.5. Requirements for diagnostic functions

4.3. Requirements for the composition and parameters of technical means

4.4. Requirements for information and software compatibility

4.5. Networking Requirements

5. REQUIREMENTS FOR DOCUMENTATION

5.1. Compliance requirements

5.2. Requirements for the composition of the documentation

6. STAGES AND STAGES OF PPO DEVELOPMENT

7. ORDER OF CONTROL AND ACCEPTANCE

7.1. Carrying out preliminary tests

7.2. The sequence of commissioning activities for each of the systems

7.3. Equipment that will be needed for commissioning, but which is not part of the system components

APPENDIX 1

I/O table for the system

LIST OF ACCEPTED ABBREVIATIONS

1. INTRODUCTION

1.1. Development name

The full name of the development is the development of application software

supply for DC boards.

Abbreviated name of the development - PPO

1.2. Application area

Field of application – modernization of DC switchboard systems

DC boards are designed to provide DC power

emergency power supply systems (EPS), diesel generator (DGS), general block

systems (OB), protection control systems (CPS), open distributed device,

systems for ensuring the safety of the main equipment (OS), managing

computing systems (UCS).

2. GROUNDS FOR DEVELOPMENT

PPO is developed on the basis of Contract No dated February 1, 2015.

2.1. Name of the Contractor's enterprise and its details Closed Joint Stock Company "Executor" (CJSC "Executor")

Location address:

2.2. Name of the Customer's enterprise and its details

Open Joint Stock Company "Customer" (OJSC "Customer")

Legal address:

2.3. The list of documents on the basis of which the PPO is created

The following documents are used as initial data (ID) for the development of application software:

- Terms of reference for PPO.

– APPENDIX 1 System I/O table

– APPENDIX 2 List of events

– APPENDIX 3 Structural diagram

The Contractor has the right to request from the Customer other IDs not specified in this list, the need for which may arise during the development.

3. PURPOSE OF THE DEVELOPMENT

The software is part of the system that performs the functions of indicating and archiving the information included in the system from input-output signals, as well as outputting messages to the operator about occurred events with a time stamp.

The purpose of the work performed is to ensure:

– registration of occurred events on DC boards, no more than 500 messages deep, in the form of a ring buffer;

– formation of a warning or emergency message in case of violation (current, voltage, insulation resistance) of regulatory or emergency boundaries;

- processing of input discrete signals characterizing the operation of the protective and switching equipment of DC boards;

– diagnostics of the controller hardware, diagnostics of hardware communication over the CanOpen network.

4. REQUIREMENTS FOR THE PROGRAM

4.1. General software requirements Application software must be developed in the Uniti XL v6.0 tool environment and the Vijeo-Designer Lite package from Schneider Electric V1.3.

The software must include:

– basic system software compatible with hardware;

– Application software, which should be developed to implement the functions of control and management of process equipment.

The software should be subdivided into PLC software and operator panel software.

All software products supplied by the application software developer must be open source to be maintainable. The developer must supply the appropriate software (software and hardware) keys that provide the ability to maintain the software of the controllers and the panel.

4.1.1. Information Panel Tool Software Requirements

4.1.1.1. The panel software must be Vijeo-DesignerLite from Schneider Electric V1.3

4.1.1.2. PC software interfaces must be in Russian.

4.1.1.3. The panel software must be adapted and optimized to work at a specific facility, taking into account the characteristics of the technological process..

4.1.1.4. The panel software should be intuitive and have the following features:

– Real time operating system

– Output with the possibility of alternating archived events;

– Display the current state of I/O signals on video frames.

4.1.2. PLC application software requirements

4.1.2.1. The PLC software must be developed using the UNITY PRO XL tool system, version 6.0 or later, by Schneider Electric, in languages according to the International Electrotechnical Commission IEC 61131-3 standard.

4.1.2.2. PLC software must be adapted and optimized for operation at a particular facility, taking into account the characteristics of the technological process. The requirements for the functions of the algorithms implemented in the applied tasks of the PLC must be determined by this TOR.

4.1.2.3. The PLC software must ensure the implementation of the following functions:

– information exchange through communication channels;

– input/output via discrete and analog channels;

– data collection and control of light boards;

– configuring system software for a specific object;

– diagnostics of software and hardware;

4.1.3. Application software requirements for receiving data via Modbus RTU

The software should allow, at the operator's command, to receive information from the controller in the form of a "slice" (clipboard) in the form of an XLS file with up to 500 lines of messages.

4.2. Requirements for the functional characteristics of the software

4.2.1. General requirements

4.2.1.1. The application software must provide the following functions:

– control of technological parameters (current, voltage, insulation resistance), the state of switching devices;

– conversion of measurements into units of physical dimension;

– smoothing (filtering) of measurements;

– formation and issuance of commands to external light indication;

– displaying the state of switching devices and the value of technological

parameters in the form of mnemonic diagrams (single-line diagrams);

– registration of events: changes in the state of switching devices,

violation of technological parameters of warning and emergency values;

4.2.1.2. It shall be possible to change the setpoints for warning and alarms. Access to change these parameters should be limited based on organizational measures (limited access to the premises).

4.2.2. Information display and signaling requirements

Organize the display of information in the form of video frames and tables sufficient to transmit current and archived information.

In the body of the video frame, the location of the displayed elements must be indicated, a single-line diagram with equipment symbols.

The message output sheet should contain information about the exact time and date of the event, a text description in Russian.

4.2.3. Information archiving requirements

4.2.3.1. It should be possible to maintain the following archives:

– an archive of events registered in chronological order by the control object and the control system, up to 500 latest messages. The organization of message storage should be formed in the form of a ring buffer.

The following events should be recorded in the archive:

– violation of technological parameters of warning and emergency boundaries;

- malfunction of protection devices and switching devices;

- malfunctions and failures in the software and hardware of the dispatching system.

4.2.4. Speed Requirements

4.2.4.1. The period for updating information on the information presentation panel should be no more than 1 second.

4.2.4.2. The frequency of polling parameters must correspond to the polling cycle of the controller and be no more than 200 ms.

4.2.5. Requirements for diagnostic functions

4.2.5.1. The application software must perform the following diagnostic functions:

– check for open or short circuit of sensors for current channels

4…20 mA;

– verification of reliability (out of the measuring range);

– diagnostics of network connections on the CanOpen bus with a check for a connection break.

4.3. Requirements for the composition and parameters of technical means

The CPUs must be type BMXP3420302. The composition of the input-output modules is specified in Appendix 9 and 10 of this Terms of Reference (TOR).

4.4. Requirements for information and software compatibility of the SHPT software should be built according to a modular principle that ensures the autonomous creation of individual software modules (PM) based on the standard library of functional blocks (FB) of the Unity Pro XL V.6 tool package.

The interaction of operational personnel with the software should be carried out at the external (user) level of the interface without maintenance and maintenance of programs.

4.5.Requirements for network interaction

4.5.1.1. Ethernet TCP/IP Network Layer Communication

The system should provide the ability to receive the current state of input/output signals to a secure enterprise network. Addresses of network devices and addresses of variables are specified during commissioning.

4.5.1.2. Communication at the Modbus RTU network level

The customer will receive an application that allows receiving data from the ring buffer and viewing messages in MS OFFICE EXCEL format. The customer will need to provide a computer with Windows XP SP3 pre-installed.

5.1. Compliance requirements

The development and execution of PPO documentation should be carried out in accordance with the requirements of:

– ESPD standards;

Documentation should be developed for the following series of PBTs - 4EA, 4EB, 4EC and 4ED separately.

5.2. Requirements for the composition of the documentation

The following documents should be included in the program documentation for the software:

– Terms of reference for the development of software.

- Specification.

- Program description.

– Operator's manual.

- Programmer's Guide.

- The program and methodology of testing at the site of the Contractor.

– Program and methodology of acceptance tests at the operation site ( ).

6. STAGES AND STAGES OF PPO DEVELOPMENT

When developing software, the following work should be performed:

-Development and approval of the Terms of Reference for the creation of PPO DC shields.

- Finalization of software in accordance with the requirements of this technical assignment.

-Development of technical documentation in accordance with the Schedule (table 6.1).

- Carrying out preliminary tests of software at the Contractor's test site using a software simulator of low-level signals.

7.1. Carrying out preliminary tests

The purpose of preliminary testing of software is to test for compliance with this specification. Tests are carried out in accordance with the acceptance test procedure.

Preliminary testing of the software should be carried out according to the agreed program + and the acceptance test method (ATM) at the Contractor's stand

Upon receipt of unsatisfactory results of preliminary tests, the Contractor must analyze the causes of the identified malfunctions, take the necessary measures to eliminate them. Repeated preliminary tests are allowed only for those requirements for which unsatisfactory results were obtained.

The following must be submitted for preliminary tests:

- PPO;

– Test program and methodology.

Delivery and acceptance is carried out by a commission, which includes representatives of the Customer and the Contractor.

Based on the results of acceptance, a preliminary test report is signed.

7.2. The sequence of commissioning activities for each of the systems

– Loading new system software (firmware) to ensure hardware compatibility;

– Checking and adjusting the software in terms of receiving field signals on the CanOpen bus. CanOpen bus setup;

– Downloading software to the system controller;

– Loading software into the visualization panel;

- Adjustment and elimination of identified deficiencies.

7.3. Equipment that will be needed for commissioning, but which is not part of the system components

Personal portable computer with Windows XP SP3 preinstalled and MS OFFICE 2007(10).

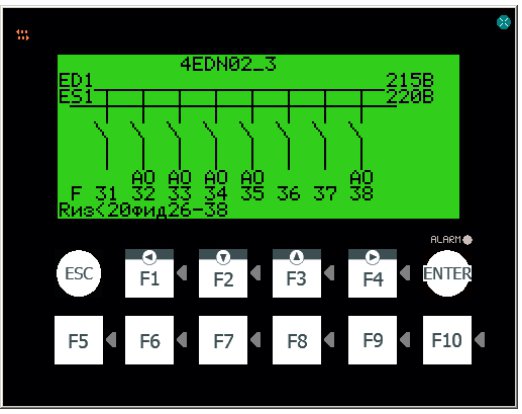

Video Frame #6 "4EAN02"

Video Frame #7 "4EAN03"

LIST OF ACCEPTED ABBREVIATIONS

NPP - nuclear power plant;

DGS - diesel generator;

ESPD - Unified system of program documentation;

ID - initial data;

KTS - a set of technical means;

IEC - International Electrotechnical Commission;

OB - general block system;

OS - system for ensuring the safety of the main equipment;

PC - industrial computer;

PLC - programmable logic controller;

PM - software module;

PMI - program and test methodology;

NDP - commissioning;

PPO - application software;

EPS - emergency power supply system (EPS);

SHPT - system of direct current boards dispatching;

CPS - protection control system;

TK - terms of reference;

TT - technical requirements;

UVS - control computer system;

FB - functional block;

SHU - control cabinet;

SHPT - direct current shield.

Be the first to comment